ADVANCED CAPABILITIES

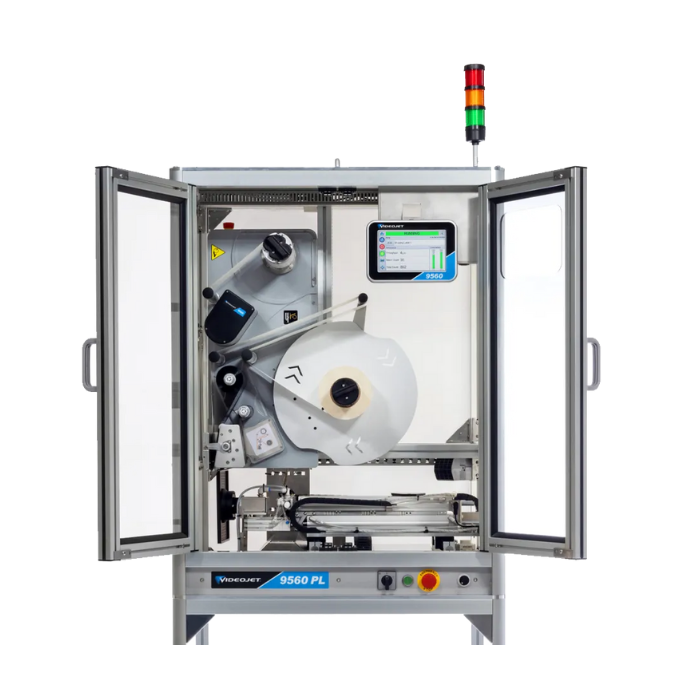

The Videojet 9560 PL is a fully automated pallet labeling system specifically engineered to function in demanding conditions. Capable of covering two or three sides and applying up to four labels, it can process up to 120 pallets per hour across diverse applications. The system verifies label accuracy and reprints incorrect labels as needed, to help ensure error-free operations. The Videojet 9560 PL also facilitates secure warehouse management and adherence to industry regulations.

Uptime Advantage

- Increase uptime from automatic reprinting of unreadable labels and a rotating tamp pad that applies the correct label in the opposite orientation.

- Zero mechanical adjustments during day-to-day operation.

- Perform label and ribbon changes in less than 60 seconds through simplest web path.

- Fully enclosed cabinet for dust protection and optional heater for temperature control.

Built-in productivity

- Never miss a label, regardless of line throughput, labeling up to 120 pallets per minute.

- Labeling arm extends up to 700mm beyond the enclosure and applicator swivels 90° in both directions for front or rear placement.

- Connectivity ready to help ensure easy, quick system management and keep increase productivity.

Code Assurance

- Virtually eliminate operator errors, helping to ensure products are coded correctly with built-in Code Assurance software features.

- Integrated bar code scanner checks for label errors, ensures readability, and validates codes so the system can automatically reprint/re-apply faulty labels to avoid manual rework.

- Precisely apply GS1-compliant bar code labels on up to three sides of a pallet.

Simple usability

- Small footprint allows for easier integration and on-board videos help simplify user training.

- Embedded Wi-Fi for easy connection to production and warehouse management systems.

- Optional second interface available for use in guarded areas.

See more: VIDEOJET 9550 – Print and Apply Labeling Machines

SPECIFICATION

| Specification | Value |

| Label Application Method | Telescopic tamp |

| Print Technology | Thermal transfer printing with Intelligent MotionTM Ribbon Drive and Direct Thermal 160mm printhead. |

| Ribbon Width | 6,4” (162mm) |

| Print Resolution | 300dpi / 200dpi emulation mode |

| Print Speed/ Throughput |

Up to 15.7in/sec (400mm/sec) Speed is dependent on the applicationUp to 120 pallets per minute, based on two labels per pallet |

| Communications | ZPL, SBPL, Cimcomms |

| Label Width/Length/Capacity | 6.5” / 4.0” to 8.0” (165mm / 100 to 200mm)/Up to 330mm spool diameter |

| Interface | CLARiTYTM Controller with interactive on-board video tutorials

TFT SVGA 800×480 full-color LCD and touch screen, WYSIWYG print preview, full on-board diagnostics, three levels of password protection, extensive language support |

| Connectivity | Ethernet, Power-over-Ethernet, Configurable I/O , Configurable I/O (24V, PNP and volt free); 8 inputs and 6 outputs, USB |

| Certification | CE, UKCA, TUV |

APPLICATIONS & VIDEO

- Beverage

- Cosmetics, Personal and Home Care

- Pharmaceutical and Medical Devices

- Dairy

- Frozen Prepared Meal

- Tobacco

- Fruits and Vegetables

Additional Applications

- Aero/Auto

- Baked Goods & Cereals

- Meat & Poultry

- Other food

- Pet Food & Animal Feed

- Fish & Seafood

- Salty Snacks

- Egg

- Candy & Confectionery

- Extrusion/Wire & Cable

Magnus –

good