A new generation of Fuji-Ace stacking robots is introduced to help reduce energy consumption by as much as 1/4 and reduce the amount of CO2 produced during the process. More powerful, stronger. A new era of industrial equipment comes from here.

FEATURE

One of the most famous Japanese manufacturers of machine parts in the world industrial market. Fuji Yusoki Kogyo Co., Ltd is one of the first units in Japan to announce and offer solutions for the transportation and handling of automation goods in the industry. Production lines of equipment manufacturers and installers in industrial parks have used laborers. And that is slowly not guaranteeing the progress of promoting the goods are transported from the chain out of the warehouse.

BENEFIT:

- Helps to transport crates too heavy (up to 20kg) – Shipped faster than human work.

- The products should be logically arranged, standardized, deft and gentle such as beer, soft drinks, chemicals, flour, canned food in general. Ensure there is no damage to the product during packing, transportation automatically.

- Made in Japan – Japanese quality

- Fully remote controlled via the control relay system

- Guide and teach your self learning machine – copy how it works. It takes only 1-2 times to guide the machine from now on.

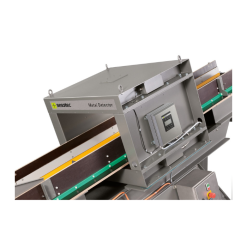

DESIGN

Industrial design

Suitable for harsh environments where dust and humidity are high

High level of damage protection

Designed to operate 24/7 in the beverage, food, pharmaceutical and tobacco industries, …

ABILITY

Depending on the product line that Robotic Fuji can lift up to 320kg.

Robotic Fuji Palletizer EC-102: 160kg

Robotic Fuji Palletizer EC – 171: 80-160kg

Robotic Fuji Palletizer EC-102: 320kg

INVESTMENT EXPENSES

In addressing the above question, Fujitec has built a scientific industrial device that solves the labor productivity problem for business owners. Find ways to reduce costs in the loading and unloading of goods. The Fuji EC-320’s fully automated robotic cargo handling equipment, including both manual and automatic operation (reprogramming). Ensure safety and efficiency in work.

Look through the details, features to the performance of the industrial product of the chain loader. We realized that the robots were carefully adjusted after installation, operating continuously from there and addressing the cargo stagnation of the conveyor belt during post-production. Reduce heavy workloads and reduce the cost of ownership.

TECHNICAL SPECIFICATION

TECHNICAL SPECIFICATIONS EC – 102

FUJI ACE model EC – 102

Multi-joint motion

Vibrant Operation

Load capacity 160kg

Speed 1200 rpm

Axis 4

Z axis (vertical) 2300mm (90.5 ”)

R-axis (length) 1500mm (59 ”)

Theta shaft (rotation) 330 ‘

Alpha shaft (neck) 330 *

Repeatability of 1.0 m / m

Memory 120 – 400 programming operations

Teaching Methodology Teaching aids

Power supply 200 / 220V, 3 phase, 50 / 60Hz

Consumption 3.5KVA / 9.2 amps

Robot Weight 700 kg

Pneumatic Supply * 5.7 CSFM @ 70psi (0.5MPa)

Note: Please contact the Admin to get detailed information.

APPLICATION & VIDEO

Seafood Industry

Rice Industry

Nghi –

Good